Protein fibres for advanced growing media.

Welcome to Grouse Fibre. We create advanced fibres and filaments from proteins, including casein fibre, utilizing biodegradable materials. These fibres are incorporated into growing media to produce advanced substrates for horticulture growers. Our innovations extend the technical capability of peat-free substrates and can significantly improve yield and reduce growing time across various horticultural environments through processes like wet spinning.

Fibre production technology

Advanced proteins

Polymer preparation

Polymer preparation

With funding from Innovate UK, we are developing protein feedstocks from abundant sources to create advanced fibres. Our research into casein from waste milk led to our first breakthrough in producing casein fibre, which is a key component in developing biodegradable materials through wet spinning techniques.

Polymer preparation

Polymer preparation

Polymer preparation

We understand that the key to success in advanced fibres production lies in meticulous attention to detail during the preparation of the dope, which refers to the polymer solutions used in creating innovative materials, including biodegradable materials and casein fibre. This precision is especially crucial in processes like wet spinning, particularly when working with technical casein.

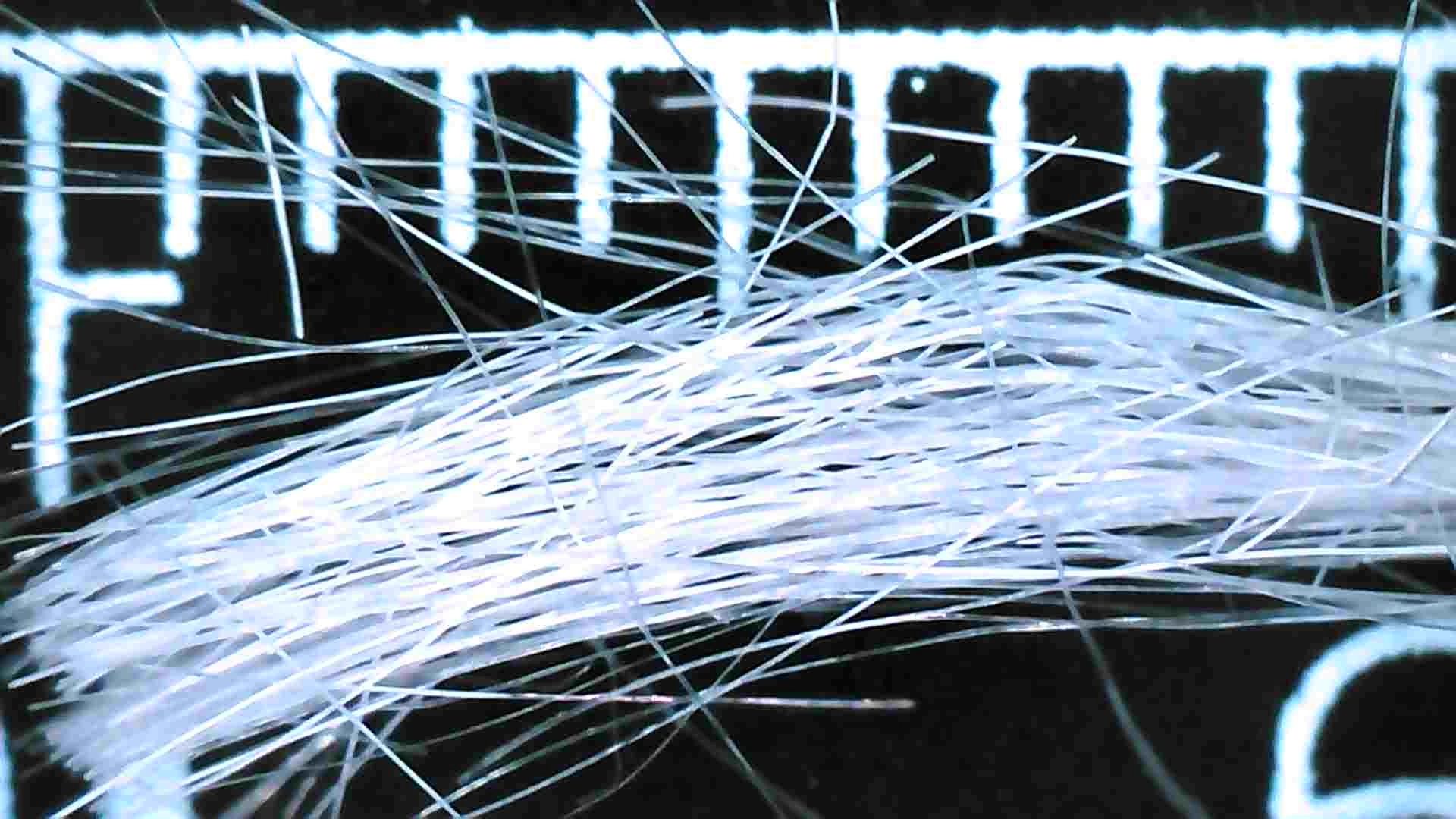

Fibre creation

Downstream processing

Downstream processing

Advanced fibres are incredibly useful. The way they form, along with the macrostructures created, is as crucial as the materials they originate from, such as biodegradable materials like casein fibre. Our expertise in novel materials, particularly in technical casein and wet spinning processes, is driving breakthroughs in materials that are difficult to process.

Downstream processing

Downstream processing

Downstream processing

Our interest also extends into the downstream processing of advanced fibres and biodegradable materials. The methods we use to cool, heat, and dry our fibres, including casein fibre and technical casein, significantly affect the crystal formation and final properties of the fibre, especially in wet spinning.

Nature builds better ingredients

We can learn from how nature uses fibres to build structures and enable life. The keratin in wool and hair, fibroin in spider silk and the spring-like triple-helix collagen in skin and muscle tissue can signpost materials of the future. We can also look to see how nature creates fibres to inform our wet-spinning and fibre forming process. Polymeric self-assembly and rapid phase-change can show inspire us to create the equipment of the future to form filaments from unique and useful materials.

Protein fibres for technical applications

Value Added

Our advanced fibres, particularly casein fibre, possess unique properties not found in other synthetics or natural polymers. With tunable hygroscopy and moisture retention, high nitrogen content, and biodegradability, these technical casein materials provide significant value for horticulture, industrial, and consumer applications, especially when utilizing wet spinning techniques.

Our Partners